Production

-

From 2007 on, Manuela Pfrunder and her team refined the design of the ninth banknote series. This challenging work was undertaken in Manuela Pfrunder’s studio, which was specially fitted with a range of security measures. One of the main reasons for it being such a challenge is because a new banknote series is not just about the design, but rather about the interplay of design and the security features. In several production stages, the images, illustrations and security features were evaluated, reviewed and adapted. Indeed, the many design changes also resulted in the theme of the banknote series being renamed. The theme is now ‘The many facets of Switzerland’.

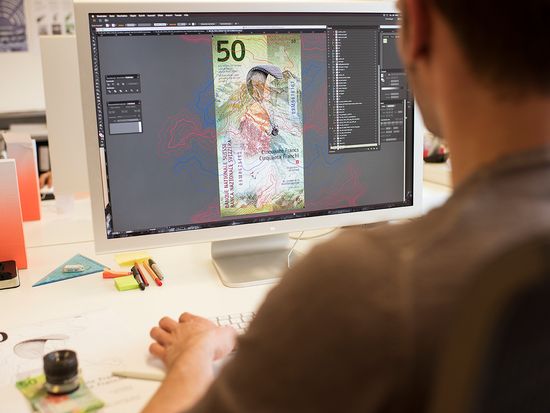

Graphic designer hard at work

Graphic designer working on a detail of the note’s front -

The notes for the ninth series will be printed on a three-layer banknote substrate (Durasafe®) supplied by Landqart (www.landqart.com). Durasafe is an innovative combination of paper and polymer (a plastic layer). The Durasafe substrate consists of two thin layers of cotton paper, which make up the front and back of the banknote. The surface thus has all the qualities of traditional banknote paper, while the central polymer core lends the note mechanical strength. The first security features are applied during the production of the paper layers that make up the front and back of the note. One of these paper layers goes through a separate manufacturing process during which the tried-and-tested security thread is applied.

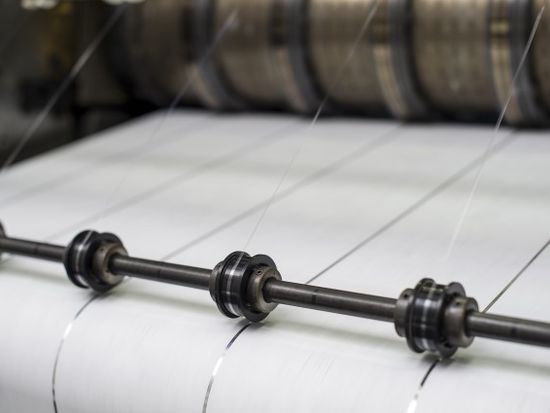

Applying the security thread to the substrate

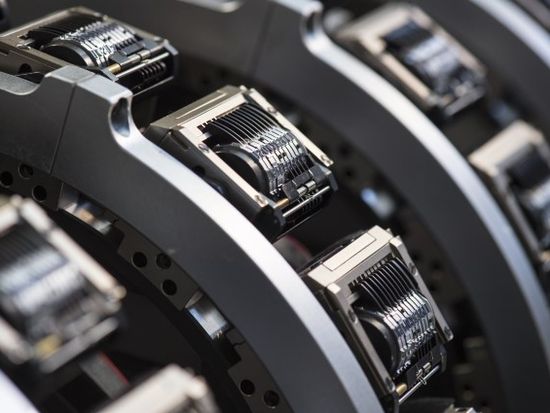

Aligning the substrate A number of other security features are then created in the Durasafe unit: the cut-out elements – the Swiss cross, the flag and a triangle – which give the note a unique appearance. Inside the ‘sandwich’ is a transparent layer of polymer, which bonds the two layers of paper together. This polymer is only visible in areas where the paper layers have been cut away. Finally, the paper rolls are cut to size and the sheets are stacked onto palettes, ready for delivery to the printer’s.

Special machine for the Durasafe three-layer substrate

Finished rolls of substrate ready for transport -

In addition to the special banknote substrate, the production of banknotes also requires special security inks which, like the notes themselves, have to meet high security standards. They must be resistant to an array of chemicals as well as to various external factors such as sunlight or a washing machine cycle. The security inks for the ninth banknote series are supplied by SICPA (www.sicpa.com) in Prilly.

Adding ink for the intaglio printing process

Ink vat and mixer -

The ninth banknote series, like the previous ones, is printed by Orell Füssli Security Printing Ltd (www.ofs.ch). Swiss banknote manufacturing involves several production steps, including seven printing procedures, as well as one application and one perforation procedure. The printing process begins with the preparation of the electronic data created by the graphic designer. Using CAD (computer-aided design) tools, these are converted into printable data and allocated to the relevant printing processes. The plates are made with the help of state-of-the-art plate production processes such as CtP (computer-to-plate). A super-simultaneous offset printing machine is then used to print a variety of multi-coloured line patterns and grids onto both sides of the paper sheets. The high-precision printing allows perfect alignment of elements on the front and back of the note, creating see-through registers in designated areas.

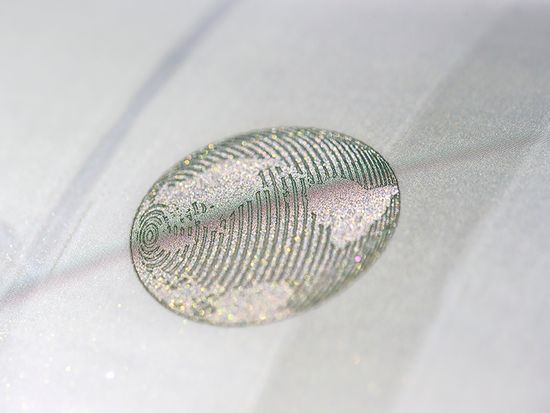

During the silkscreen printing procedure, an iridescent band is applied to the back of the note. This makes the note more stable. The foil application unit applies the security strip, which was developed by Leonhard Kurz (www.kurz.de) and consists of multiple layers; among other things, it contains red and green numbers. If you look more closely, you can see metallic microlettering and the value numeral of the denomination shining in either silver or rainbow colours.

Open offset printing press

Feeding in the security strip prior to application In a second silkscreen printing procedure, a shimmering globe – which features on each new denomination – is applied to the banknote. The appearance and colour of the globe change depending on the viewing angle. Magnetic pigments are added to the ink in order to achieve this effect.

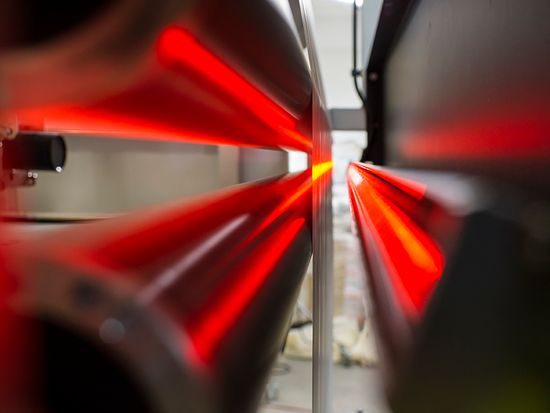

Inside the print cylinder

Detail on outside of the print cylinder One of the most important stages in the printing process is intaglio printing – a technique that is used on both the front and back of the note. Coloured inks are applied to the grooves in the printing plates. The ink is applied to the paper under high pressure and at a high temperature. This creates a relief structure that can be felt when touching the note.

Putting the finishing touches to the printing plate

Detail of the numbering stamp In a further step, the Swiss cross is added using a perforation procedure (Microperf®). Then, once the serial number has been applied via the letterpress printing technique, the notes are varnished to protect them against soiling. The finished paper sheets are subsequently cut to size and arranged in bundles. The print quality and security features of each and every banknote are then checked in a testing unit, and any defective notes are rejected. The final step sees the notes packed up, ready for delivery to the SNB.

-

Upon delivery at the SNB, spot checks are carried out on the freshly printed banknotes. Once the quality assurance process has been completed, the new banknotes are released for circulation.